HELP US GET MOVING BY JOINING THE ‘5551 CLUB’.

FUNDS RAISED FROM THIS INITIATIVE WILL ENABLE US TO COMPLETE MAJOR WORK ON THE MOTION.

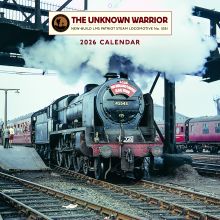

AVAILABLE NOW!

Upcoming events

-

28/02/2026 - 00:00 to 01/03/2026 - 23:45

-

19/03/2026 - 00:00 to 22/03/2026 - 23:45

-

21/03/2026 - 10:00 to 22/03/2026 - 16:30