Reduced to £5.00 plus £2.50 p&p

Engineering Update - July 2023

Encouraging progress on The Unknown Warrior has been made in the period since the last report.

5551 Chassis. West Shed, July 2023. Photo by Keith Riches

Main Frame Assembly

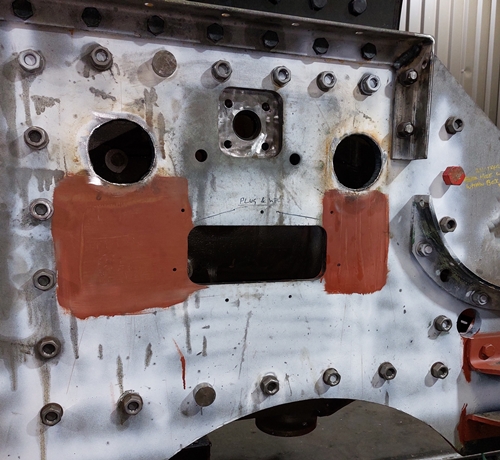

Work continues on the Main Frames assembly with good progress towards completion of the repairs. The welding required on the frame plates was finally completed in June. The welder from Tyseley travelled up to carry this work out on-site and we have all of the essential documentation of the work completed.

Frame welding repairs in progress. Photo by Keith Riches

Plugs in place and instructions for the welder. Photo by Keith Riches

Building up the ring of weld in progress. Photo by Keith Riches

A batch of holes following completion of welding, but before grinding back to a smooth surface. Photo by Keith Riches

Completion of this work has allowed a number of components to be refitted following re-drilling of the mounting holes.

As reported in the last Warrior the Inside Cylinder has been refitted into the chassis ahead of the installation of the fitted bolts. The installation of some of these bolts is dependent on the availability of other parts such as the Outside Cylinders and Bogie Centre Pin Casting as some bolts fix more than one component to the frames.

A view of the front end of 5551 showing the Inside Cylinder in position through the LH Frame Plate. Photo by Kevin West

Following completion of the physical work of manufacturing and fitting all the parts required for the Front Buffer Beam work is being finalised on the necessary paperwork covering this work. Once completed it will be submitted to Ricardo for comment and then used as a template for all future paperwork packs.

A couple of missing access holes have been drilled in the right-hand Main Frame alongside the Inside Cylinder to allow access to the Lubrication system.

RH Frame showing to 2 added access holes. Photo by Kevin West

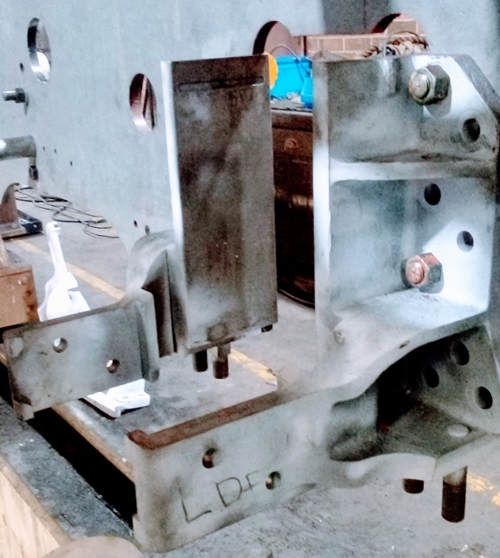

Work is progressing on installing the Brake Hanger Brackets and the Horn Guides. All of the Horn Guides are now back on the Frames and the Horn Block Ties have been temporarily refitted to stabilise the chassis. The fitted bolts to finally fit these parts have been manufactured and are planned to be installed in the coming weeks. Some of this work has been progressed by our volunteer group under the supervision of Simon Scott.

The Horn Guides for the leading Axle mounted onto the LH Frame Plate. Photo by Neil Kinsey

The castings which were sent to Ian Riley’s works at Heywood, Lancashire for repair have been completed and we await their return to West Shed. It is pleasing to report all this work has been completed with all the parts passing the final inspections and all paperwork in place to cover the work. Parts included in this work are the Outside Motion Brackets, Motion Girders, Rear Motion Girder Bracket and a Frame Stretcher. We had received the costings for these repairs and were considering whether to go ahead and repair or to see if replacement was a more cost-effective way forward. The next we heard was that Riley’s had completed the repairs and all parts had passed the subsequent inspections.

As we had not authorised this work we entered into negotiations with the result that we obtained a substantial discount from the original quoted cost.

Back at West Shed all the parts which have been subjected to hardness testing have passed and are now cleared for use on the locomotive. Several parts were found to be borderline after the initial round of testing and have been subjected to a repeat testing and found to be acceptable which is a relief. We thank Mike Ames, our volunteer metallurgist for undertaking this work at short notice.

A view between the frames of 5551 at West Shed. The recently repaired Stretcher is mounted onto the rows of vertical holes visible on the left. . Photo by Kevin West

On the chassis, the Smokebox Mounting Brackets have been fitted to the tops of the Frames and the smokebox remounted. Following the refitting of the Platform Valance Angles the Platform Plates will start going back on, but the Boiler Expansion Brackets need to be fitted first which can now be done following the recent welding work that has filled a number of incorrectly positioned holes around the bracket location. The cab has also been placed back onto

the chassis.

Motion

Machining of motion fittings continues as time allows.

Cylinders

The Outside Cylinders are at Ian Riley’s for replacement of the Liners. The order for these has been raised and is expected to be completed within the next couple of months.

Driving Wheels

The Driving Wheel castings have all been completed and all have passed the post proof machining checks and final quality inspections.

Chairman Colin Hall inspects one of the new Driving Wheels at William Cook. Photo by Simon Scott

Five of our new Driving Wheels in this view at William Cooks. Photo by Simon Scott

A close up view of one Driving Wheel showing the quality of the casting. Photo by Simon Scott

Our wheels have been delivered to Ian Riley’s works ahead of assembly onto the axles. We are now working on the drawings and specifications required to allow this work to be undertaken.

The Balance Weight Plates and balancing lead following recovery from the old Driving Wheels. Photo by Kevin West

Bogie

The new Bogie Wheelset has had the wheels pressed off the axle to allow the wheel casting to be tested and inspected in the absence of quality documentation.

Boiler

HBSS have continued working on our boiler to an agreed programme over the period covered by this report. Current work being undertaken is focused on preparation for the fitting of the Crown Stays.

The Boiler on display at HBSS Open Day – 15th July 2023. Photo by Pete Sikes

We are planning the restart of work to an increased schedule in the Autumn which will bring the boiler up to the stage of requiring the tubes to be fitted.

A view inside the Inner Firebox. Photo by Pete Sikes

Members of the 5551 team were pleased to support the HBSS team at their works open day on 15th July.

Tender

Since our last report, work on the tender has been suspended pending the outcome of our strategic review.

The Tender Wheelsets have been moved to West Shed following the Spring inspection. We believe they will be acceptable for heritage line use in the future, but not suitable for main line use without extensive rectification work. We are considering how to proceed with the tender as part of our review, which will be a decision for the future.

The Tender Wheels at West Shed. Photo by Kevin West