Reduced to £5.00 plus £2.50 p&p

Engineering Report - May 2023

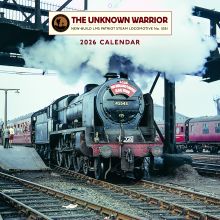

Work on The Unknown Warrior has continued over the period since the last report.

5551 Chassis. West Shed, April 2023. Photo by Colin Hall

Main Frame Assembly

Work continues on the main frames where parts are finally being reattached following testing and repair as required. We are still experiencing delays due to the unavailability of the certified welder from Tyseley Locomotive Works to undertake the work required on the frames. He is fully occupied with work on the Vintage Trains vehicles and getting a release for our work has not been possible despite several promises. Everything is ready at the West Shed including all the plugs having been made ready for welding into position. Simon Scott continues to try and get this work completed as soon as possible as we will soon be approaching the time when any further delay will impact on the reassembly of components.

A view of one area that requires welding work on the Frames. The plugs have been made are ready to be welded into position. Photo by Colin Hall

The assembly of the Front Buffer Beam including the brackets required for air braking has been completed. The Inside Cylinder has been refitted after passing all required inspections and the required fitted bolts have been manufactured and supplied. Fitting these bolts will follow shortly.

Front Buffer Beam. Photo by Colin Hall

The Brake Hanger Brackets and the Horn Guides are also being reattached to the main frames after also passing all required tests and inspections. Once again the fitted bolts have been manufactured and are in the process of being fitted.

Brake Hanger Brackets being fitted. Photo by Colin Hall

Of the other parts removed from the chassis they have all now been hardness tested and MPI inspected for casting defects and those requiring repair have been sent to Ian Riley & Sons for quotations to cover the required work. The first batch of costings for this work is now to hand and we are looking at the best way forward. In some cases the cost of repair quoted looks almost as much as making new, so comparative costs are being sought before decisions are made on individual items. Repair of the Axlebox Horn Ties has been signed off as these were a low cost repair.

The engineering team inspect the Motion Girders following hardness and MPI tests. Photo by Colin Hall

Away from the West Shed the new Dragbox is ready for assembly and welding at Tyseley following delivery of all the profiled plates, although this is will follow on from the welders visit to West Shed to carry out the frame work detailed above.

Design work relating to the mounting of the Air Pump required for the air brake system continues.

Kevin West and Simon Scott discuss details of the Main Frame drawings at West Shed. Photo by Colin Hall

Motion

Machining of motion fittings continues as time allows.

Cylinders

The Outside Cylinders have moved to Ian Riley for replacement of the liners which were disturbed during the Port Bar welding work. This was anticipated during the planning for the cylinder work.

Driving Wheels

William Cook Cast Products report that they continue to experience issues with equipment and resources to complete the amount of work necessary in the final stages of their production process. Three of the wheels are awaiting dimensional inspection prior to stress relieving. The remaining five are undergoing surface and dimensional upgrading, prior to dimensional inspection and then stress relieving. Last weeks forecast said that they should all be completed by 12th June.

Bogie

The Bogie Wheelsets have been reassessed as part of the design review. The original set of wheels and axle obtained from 8F No. 48518 has now been declared unfit for further main line use as the parts are out of specification for use on a Patriot-design bogie. We are investigating possible short term use of this wheelset for heritage line use whilst a replacement wheelset is manufactured.

The new wheelset also requires major work as the drawing used to manufacture the axle has now been declared as unsuitable for use on a Patriot. The bearing journal is a smaller size than specified on the bogie used on the Patriot and Jubilee classes so will turn faster than the correct larger size at speed with possible heating of the journal. There are also questions regarding the weight carrying capacity of the smaller journal which would have to be proved as being of no issue before allowing use on the main line.

We did obtain independent engineering advice free of charge to help us decide the way forward on these issues. Sourcing a new axle is in progress.

Boiler

HBSS continue working on our boiler to an agreed programme. We are planning a restart of work to an increased schedule in the Autumn which will bring the boiler up to the stage of requiring the tubes to be fitted.

Tender

Following on from the planned revised Tender Body design that was explained in the last Warrior, we need to consider the increase in weight implications on the chassis and running gear. In the light of this work we have agreed a freeze on any further work on the chassis with Leaky Finders.

The Tender Wheelsets have been inspected by an independent body and the report has raised a number of issues which we need to consider before making any decisions.