Reduced to £5.00 plus £2.50 p&p

Engineering Update - May 2020

Work on The Unknown Warrior has continued at various location since the last report.

Construction of 5551 continues at a number of locations.

Physical work on 5551 has been very slow since the last report as can be expected due to the onset of the Coronavirus pandemic outbreak. Virtually all our suppliers have had to close down or if they are still open they are working with reduced staffing levels and only working on safety critical or key work projects. Unfortunately for us, whatever we think of 5551 we do not fit into these categories!

A vision of the future, 5551, 6233 & 6203 outside the West Shed. Drawing by Neil Kinsey

The West Shed has been closed for most of April, although a limited amount of machining work has been possible in private workshops on certain small parts. It is hoped that the West Shed will be opening up on a limited basis in the near future to allow some work to re-start, but we are in the hands of the Government and scientists.

On a personal note, the first four months of this year have been interesting to say the least for your CME! My daughter and her husband moved home at the end of January, so dad was invited to help them move! Distance was not great from old home to new, Quorn to Mountsorell alongside the Great Central Railway. The main move took place on the Friday to accompaniment from whistles from the GCR winter gala. I was given the day off on Saturday to attend our project board meeting at West Shed before we started ripping the house apart on Sunday for the required renovations!

The following week I found out my own house move was to go ahead at the end of March. Jo and I were moving from Towcester to Hinckley about 40 miles. Not only the standard house contents but my full engineering workshop and large steam models had to be transported. Payback time for my son in law who offered his works van for a couple of trips to move the workshop, which I didn’t want to trust to the removal company, while I moved my models shuttling back and forth in my car over a week.

Our CME working on a Great Central Railway 9N class tank in his workshop. Photo – Joanne Baddock

Ten days after moving in the workshop was fully up and running ready for some running repairs on a couple of model locos required for an exhibition on 14th March. So most of February and early March were taken up with thee house moves and meant little time for Patriot work. Finally, at the end of March my daughter gave birth to my first grandchild. George was 6 weeks premature and born on the day before lockdown was announced, so as yet I have not met him. Thankfully he is strong, doing well and back home with his mum and dad after a couple of weeks in hospital. I look forward to being able to introduce him to the delights of steam locomotives and particularly 5551 in the future. With a name like George he could be just the sort we need to keep locos running after our time is up?

Paperwork

The one area where progress can be made in these difficult time relates to office based paperwork collation and record keeping.

Our accounts team have retained electronic copies of purchase orders back to the start of the project. These are archived in the financial year to which they relate, but there was no central register of orders raised. Our Treasurer, Neil Collinson has sent me copies of all the orders and I started creating the register. This is now being outsourced to my second daughter who has been furloughed from her work with The Prince’s Trust. This has freed me up to use the information on the order register to populate the Locomotive Master Parts List.

The important document will contain information on every component on 5551, including every work item required to manufacture and fit it to the locomotive. The relevant works orders are an important link in identifying what was done by whom and when.

I have always maintained a parts list as part of my own work to try and keep track of progress. The master parts list has been developed on from this to include details of each order and operation. Later we will be able to expand it even further to include hyperlinks to the material certificates and other paperwork so everything is in one database. It is one task I did not sign up to do, but without it we will never obtain the required approvals. It is very time consuming, incredibly boring and will take months to complete fully. Thankfully, my workshop is only a few paces away, so when I can’t face trying to work out the meaning of another badly written order I can spend an hour making another part for my new model loco!

A screen grab of part of one page of the Master Parts List spreadsheet. This is about one third of the items that make up the Locomotive Main Frame Assembly. Parts are listed vertically, tasks to manufacture and fit are shown horizontally.

There are another 25 sheets like this already with many more to follow.

Llangollen Paperwork

We have re-established contact with Llangollen Railway, particularly regarding whatever paperwork they have relating to 5551? We understand they have significant issues regarding the financial security and future of the railway, even before the coronavirus hit, but we have pressed them to look again in their archives for any documentation they have. Once again the search for our papers is a time consuming process and the resource of manpower is limited at normal times but even more scarce at present. We are mainly talking about material certificates for parts manufactured for us or test certificates for parts inspected whilst at Llangollen. If this documentation cannot be found there are ways to get parts tested, but this has manpower, time and cost implications. We will be looking for the recovery of any costs relating to paperwork that cannot be provided.

PTS Training

The training is obviously on hold until the current conditions are lifted.

Chassis

Princess Royal Class Locomotive Trust, West Shed, Midland Railway Centre.

Work has continued on a limited basis at West Shed on various aspect of the locomotive chassis.

5551 and 6233 in West Shed. Photo – Andy Collinson

Bogie

Drawings need to be finished and submitted to Ricardo Certification for the proposed modified Bogie Stretcher. Once this is done we can progress getting the parts cut and the new Strretcher fabricated.

Bogie Wheels

The Bogie Wheelset is still at Ian Riley’s to have the replacement tyres fitted. We anticipate this will be done shortly after the lockdown has been lifted.

Snifting Valves

The Snifting Valves are mounted on the main steam inlets to each cylinder. Their purpose is to allow air to pass through the cylinders when the locomotive is moving with the regulator shut. Without this air a vacuum can be created in the cylinder chambers and act as a brake on the locomotive movement. With the regulator open the positive pressure in the steam pipes closes the valve and no air is admitted. When the regulator is shut and the pressure in the steam pipes falls below normal atmospheric pressure, the valve open and admit air to pass through the cylinders.

Tapping the cover holes. Photo – PRCLT

We obtained 3 valve bodies in the early days of the project. We believe these are original ex-locomotive parts, but they all are showing signs of wear and there were no internal valve parts. PRCLT have a full set of casting patterns for these valves, they are standard on many LMS classes of locomotive including the Duchess. So castings for 3 completely new valve assemblies and some spares for the Duchess have been obtained and are in the process of being machined.

The three Snifting Valve Bodies following machining. Photo – PRCLT

The Bodies are Cast Iron with bronze valves.

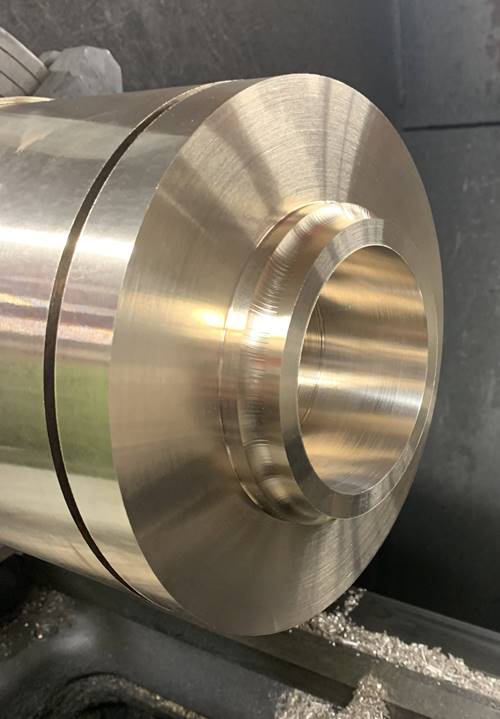

A Valve Head in process of turning. Photo – PRCLT

A Valve Ring sits on the finished bodies. Photo – PRCLT

The castings for 6 new Drain Cock bodies are ready to collect from our suppliers. These will be moved shortly to allow machining.

Outside Cylinders

The replacement Outside Cylinder Covers have been cast and await movement to be machined. This will most likely be done at the Great Central Railway works in Loughborough.

The castings for the new Drain Cocks have been delivered and await machining.

Drain Cock Castings and patterns. Photo – Premier Patterns

Brakes

Work is to be undertaken on the Drag Box under the cab to fit the mounting studs for the Brake Cross Shaft Bracket and the Steam Brake Cylinder.

Air Brakes

PRCLT engineers are working on the design and specification for the air braking system. Drawings are being prepared to submit to Ricardo for approval.

Motion

Transport to move the motion parts from Statfold Barn to West Shed had been arranged for Tuesday 24th March, but West Shed was closed for lockdown that morning, so the parts remain at Statfold for the moment. Movement will be re-arranged as soon as lockdown is lifted.

Corrective work on the Axleboxes is ready to start once West Shed re-opens.

Crank Pins

As reported previously, Ricardo Certification are happy with the material specification and the methods to be used for assembly. We just wait for Ian Riley’s to return to work for the assembly to be undertaken. Once complete the Wheelset will move to Tyseley Locomotive Works for the axle journals to be polished

Boiler

Heritage Boiler Steam Services continue making good progress on the Boiler assembly.

HBSS have been doing the final fitting of the crinoline and also fitting the firebox cladding sheets. Marking them out with the positions of the screws and tapping them. The holes have also been drilled for the washout plugs. Cladding bands should arrive soon.

Firebox and Backplate Cladding underway at HBSS. Photo – HBSS

Firebox Cladding underway at HBSS. Photo – HBSS

Firebox Top Cladding underway at HBSS. Photo – HBSS

The replacement castings for both the Dome and Cover have been fully tested and approved. They will be dispatched for machining once lockdown restrictions are lifted before passing back to HBSS for fitment to the boiler barrel.

New castings for the Palm Stays to a revised design have been delivered ready for machining.

The Superheater Header has been machined to allow the casting to be pressure testing.

Boiler Fittings

Work continues on sourcing the various fitting we need for 5551.

Main Line Running Gear

Work continues on various elements of the provision of the main line running gear.

Tender Chassis

Work has continued at Leaky Finders on the refurbishment of the Tender chassis.

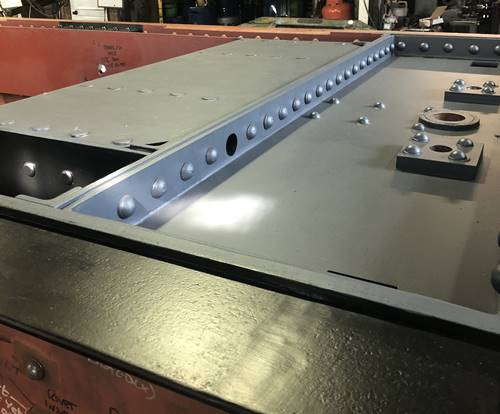

The Tender Chassis nears completion at Leaky Finders workshop. Photo – Leaky Finders

All the Horn Guide fitting and riveting has been completed.

The left side Leading Horn Guide.. Photo – Leaky Finders

The final major task on the Frame structure is to finally rivet the new Rear Drag Box into the Frames. This is not possible to be done at the moment due to the staff having to social distance!

The Tender Trailing Dragbox wait for final riveting.. Photo – Leaky Finders

The Leading Tender Leading Dragbox with the Drawbar Pins in position.. Photo – Leaky Finders

The chassis is being painted to protect all the major work undertaken, with everything in undercoat and a single top coat almost complete, apart from the area where the Rear Drag Box will be riveted in the future.

The front end of the Frames and Leading Dragbox following painting. Photo – Leaky Finders

A view of the Tender chassis looking back to the Trailing Dragbox following painting. Photo – Leaky Finders

Brake and Spring components are also being painted to provide surface protection.

The Spring Links following painting. Photo – Leaky Finders

The new Handbrake Screw and Nut with the original worn part behind. The new screw still has to be screw cut and the old has had the top of the shaft cut off. Photo – Leaky Finders

Tender Tank Design

No progress since last report.