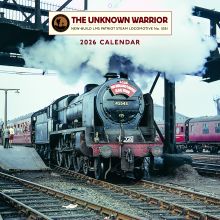

Reduced to £5.00 plus £2.50 p&p

Engineering Update - February 2020

Work on The Unknown Warrior has continued at various locations since the last report.

5551 in The West Shed. Photo – Andy Collinson

To begin, I would like to apologies for my nonappearance at our AGM on 7th November. I had been suffering from a chest infection for the week prior and was in no fit state to travel to West Shed. Even if I had, I had lost my voice, so would have been unable to give any presentations.

Physical work at PRCLT has slowed for a variety of reasons over the last few weeks, but this does not mean that work on progressing the construction, assembly and certification of 5551 has stopped, in fact much the opposite.

Following the November resignations of our Chairman David Bradshaw and Engineering Director Steve Blackburn we were not in a good position, as it had always been expected that Steve would head up the gathering and cataloguing of documentation required for certification purposes. With the board now restored to full strength following the appointment of Colin Hall and Keith Riches, a complete review of our approach to obtaining the required approvals has taken place and meetings held with all the necessary bodies we must engage with to obtain the final sign off. Colin Hall has outlined the organizations we have contacted and progress on this important work will be reported over the coming issues of The Warrior.

One area that has been brought into sharp focus by these discussion is the paperwork. This comprises such things as material certificates for every part of 5551, manufacturing information, competency certificates for the staff that have undertaken work on components. Without this we get no approval and the loco cannot run.

The first requirement is to bring together as much paperwork as we have for a first assessment. Beyond that we need to bring together everything from our suppliers and contractors. We have a number of people lined up to help do this, but they need to know what they are asking for. To that end my immediate task is to compile lists of parts supplied by each supplier.

At the board meeting at the end of January, Colin provided a complete report on the process to obtain approval and outlined the work we will need to undertake. The board were asked to vote if they wished to continue with the aim of attaining main line approval and the result was a unanimous yes.

6233 Duchess of Sutherland undertakes a test steaming at West Shed 4th Feb 2020. Photo – John Hastings-Thompson

As part of the learning process of what is required to run a locomotive on the main line a number of board members and volunteers are to undergo PTS (Personal Trackside Safety) training. This will allow us to accompany 6233 on its main line outings to find out first hand.

Chassis

Princess Royal Class Locomotive Trust, West Shed, Midland Railway Centre.

Work has continued at West Shed on various aspect of the locomotive chassis.

View inside the Frames where the Firebox will fit. Photo – Andy Collinson

Bogie

Ricardo Certification have looked at the proposed modified Bogie Stretcher and can see no issues. We now need to finalise the drawings and make a full submission for approval.

Bogie Frame at West Shed 4th Feb 2020. Photo – John Hastings-Thompson

Bogie Wheels

The Bogie Wheelset obtained from ex Barry 8F 48518 was always known to have tyres with the back to back being slightly over specification, but it would be ok when used as the trailing wheelset on the bogie. Following a recent inspection by our approval authority it was suggested that this may no longer be acceptable. The inspection also questioned the surface finish of the centre section of the axle, which has some pitting and corrosion following many years in service and standing in a scrapyard. The wheelset has been sent to Ian Riley & Sons to have the axle skimmed in the wheel lathe to remove the pitting and check for no deeper flaws. The opportunity to fit new tyres to correct specification at the same time has also been taken.

Cylinder Relief Valves & Drain Cocks

These have been temporarily fitted to allow the Drain Cock Operating Gear to be trial fitted. An amount of work has been required as expected to get the parts to work smoothly. The operating gear has now been removed to allow access for other work local to the cylinders.

Cylinder Relief Valves, Drain Cocks and Operating Gear trial fitted to the LH Outside Cylinder. West Shed 4th Feb 2020. Photo – John Hastings-Thompson

View underneath the Inside Cylinder showing Cylinder Relief Valve, Drain Cock and Operating Gear trial fitted. West Shed Nov 2019. Photo – Andy Collinson

The order for 6 new Drain Cock bodies has been placed and we are waiting for the castings. These will then be sent for machining and manufacture of the internals before fitting to the Cylinder Relief Valves. The original 6 assemblies we have will be offered for sale.

Outside Cylinders

The cylinders for 5551 were made very early in the project, both being manufactured to original drawings dated 1927 for the Royal Scot class. Identical cylinders were used on the Patriots. One feature on the Inside Cylinder are 3 ribs that run the length of the centre section of the valve chest to guide the valve head when it is fitted or removed from the cylinder for maintenance. These ribs are not shown on the drawing for the Outside Cylinders, so have not been included on the casting. Concern has been raised by the PRCLT engineers about possible difficulties on removing the valves. Later LMS designs including the Duchess have these guide ribs, although the Great Western Castles do not, according to Alastair Meanley from Tyseley Locomotive Works. The PRCLT engineers believe it will be beneficial to have these in place so some work has been undertaken to look into the feasibility, although fitting them in situ will not be easy.

LH Cylinder Assy, West Shed 4th Feb 2020. Photo by John Hastings-Thompson

The replacement Outside Cylinder Covers have been cast and await movement to be machined. This will most likely be done at the Great Central Railway works in Loughborough.

Rear Cylinder Cover castings. Photo Premier Patterns

Brakes

Work is to be undertaken on the Drag Box under the cab to fit the mounting studs for the Brake Cross Shaft Bracket and the Steam Brake Cylinder.

Brake Cross Shaft Bracket at West Shed. 4th Feb 2020. Photo – John Hastings-Thompson

On the locomotive chassis itself, we are starting to investigate the fitment of air braking equipment. This will require a steam operated air pump plus plenty of ancillary equipment. PRCLT hold most of the parts in stock and the design will be similar to that fitted to Duchess of Southerland.

The pump will be mounted between the frames on one of the Frame Stretchers so will not be visible and make a change to the original appearance of the locomotive. This new line of thinking will allow maximum operating flexibility with train operators in the future.

The proposed modifications for the Spring Hanger Pins and Brake Hanger Pins to add a secondary retention method have been approved by Ricardo. Drawings can now be prepared and the parts manufactured. Work continues on completion of the lubrication system, with modifications to the clipping of the pipes in line with their main line experience.

Repainted Brake Cross Beams. Photo – Gavin Shell

Motion

The motion components have been at Statfold Engineering since spring of last year for repair of the bearing brasses and white metal. The only parts actually worked on have been the Outside Connecting Rods which have had new Bearing Brasses made and white metaled. No further work can be completed until the Crank Pin work has been finished and the diameters confirmed. This will allow the white metal to be machined to give the required clearance to the Pin.

We have decided as part of the overall assessment of the chassis to bring all parts back to West Shed. This will allow all parts to be inspected and measured to check the centre distances of all the Rods to ensure all the tolerances and clearances for the motion work and axleboxes is correct. This is much easier to do at one place rather than spread over a number of locations. We also need to have the legacy parts inspected and approved for further use. We know various parts were inspected at Llangollen shortly after they were acquired. We now need to obtain copies of the testing paperwork to submit to Ricardo Certification.

The Axleboxes are ready for corrective work once the Wheelsets are finished.

Driving Axleboxes await attention at West Shed. 4th Feb 2020. Photo – John Hastings-Thompson

The Inside Expansion Link has been finally fitted following work on the bearings to obtain correct fit and clearances.

Inside Expansion Link in position. West Shed. 4th Feb 2020. Photo – John Hastings-Thompson

The Reverser Shaft components have been machined and we await a final assembly and inspection to ensure everything is correct. There is a little work required to the cosmetic finish.

Reverser Shaft Assembly. Photo – Kevin West

Crank Pins

As reported in the last report we had obtained a quotation for the complete replacement of the Crank Pins. This very quickly turned into a full order and the Driving Wheels were dispatched to Ian Riley & Sons in early December. The Crank pins were removed and new pins manufactured ready to fit. A brief delay followed to ensure Ricardo Certification were happy with the material specification and the methods to be used for assembly. This is now complete and the new Pins are expected to be fitted early in February. The final work required is to polish the axle journals to remove some slight pitting. Due to our wheels being slightly too big for Riley’s wheel lathe this will be undertaken at Tyseley Locomotive Works.

Driving Wheels

The PRCLT volunteers have continued work on the painting of the Driving Wheels and Crank Axle.

Crank Axle following completion of painting. Photo – Gavin Shell

Combination Levers

The original parts will be inspected along with the other legacy motion work before a final decision on replacement is made.

Away from practical work, we continue working on preparing for the discussions that will need to be undertaken with various supplier regarding past work. This work will require a vast input on our behalf and we expect will continue for some time before it is complete. Due to this the output from our design office is less than we had hoped for.

Boiler

Heritage Boiler Steam Services continue making good progress on the Boiler assembly.

Recent work has included fitting the Transverse Stays. These run across the Firebox above the inner Firebox and hold the Outer Firebox side plates against the pressure inside the boiler.

Transverse Stays inside the Firebox. Photo – HBSS

Left hand side of the Firebox showing the threaded ends of the Transverse Stays. Photo – HBSS

The replacement Dome has been cast and has passed the required testing. The Dome Cover unfortunately failed the testing so another is due to be cast in early February. Once both parts have been fully tested and approved they will be dispatched for machining before passing back to HBSS for fitment to the boiler barrel.

New castings for the Palm Stays to a revised design have been delivered ready for machining.

HBSS have also been manufacturing the crinolines used to support the cladding sheets on the boiler barrel and around the firebox. Thankfully we have the original drawing for this assembly, which has been a great help, although the drawings for most of the smaller parts used is missing, so HBSS have spent a great deal of time working out these parts from very basic information.

A selection of views of the Crinolines fitted to the boiler barrel and firebox. Photos – HBSS & Kevin West

Work on the Firebox Doorplate has progressed to making and fitting the cladding sheets.

Boiler backhead showing cladding sheets. Photos – HBSS

The Longitudinal Stays have now been ordered following final approval of the manufacturing process. The original design uses single piece stays and when we first started the boiler build material of the required length was available. When we came to order the material the length we required was not available in the UK and would have to come from Europe. The cost was also £80,000 against the £10,000 originally quoted when we started. We then started investigating methods to use two pieces of material joined by a screwed buckle. The design has been approved by our boiler insurer and HBSS have found a manufacturer to produce the parts for £22,000. Still twice the original budget cost but much less than using single piece stays.

The Superheater Header has been sent for trial machining to allow the casting to be pressure testing.

Boiler Fittings

Simon Scott from PRCLT has arranged the short term loan of a number of Fowler boiler fittings from the East Lancs Railway Crab 2-6-0 for us to evaluate for use on 5551. This will be an ongoing project for the next few months, making drawings, having patterns and castings made and machined.

A view of the cab fittings of LMS Crab 13000 on display at the National Railway Museum, York. Dec 2019. These are very similar to the fittings required for 5551. Photo – Kevin West

Main Line Running Gear

Our meetings with the A1 Trust and Ricardo Certification has provided information regarding the fitment of all elements of the main line running gear.

Tender Chassis

Work has continued at Leaky Finders on the refurbishment of the Tender chassis. The main focus at present has been the refitting of the Axlebox Horn Guides to correct tolerance.

Horn Guides riveted in position. Photo – Leaky Finders

Tender Buffer Beam following drilling. Photo – Leaky Finders

Also undertaken has been the refurbishment of the Spring Link Hangers and Brake Hanger Brackets. Bushes have been fitted and machined where required to bring all holes back to the required sizes and tolerances. A number of new Spring Link Hangers have been required where the originals were beyond repair.

One of the Spring Link Brackets being bored after a new bearing has been pressed in.. Photo – Leaky Finders

A new Spring Link. Photo – Leaky Finders

Tender Tank Design

With the information provided regarding the Main Line Running gear we will be able to finalise the design of the Tender Tank and place the order for the tank manufacture. Another item that will need to be considered is the requirement to install 4 air reservoirs under the tender for the air brake system.

BR Vanwide Van

Following our arrival at The West Shed our storage/workshop van has been housed inside the shed. Our volunteers have taken advantage of being inside to do some repairs to the roof covering and doors followed by a repaint.

Neil Kinsey takes a break from running our sales stand to work on our Vanwide Box Van. Photo – Gavin Shell

New roof covering. Photo – Gavin Shell

Work complete. Photo – John Hastings-Thompson