Reduced to £5.00 plus £2.50 p&p

Engineering Up-date - February 2019

Work on The Unknown Warrior since the last report has concentrated on establishing the true condition of vital components and assemblies.

The first stage was to get a full independent mechanical inspection of the chassis completed and this was undertaken by Andy Forster, former CME of the West Somerset Railway, on 4th and 5th December at Crewe Heritage Centre. The results confirmed our own initial thoughts, plus a couple of other issues, but nothing of a serious nature. The first priority was to rectify the issues raised along with progressing ongoing work on the lubrication system. Nigel Day and our team of volunteers have made fantastic progress in the far from ideal conditions in the Heritage Centre Exhibition Hall over the last three months. We are hopeful that circumstances will change in the near future to enable better facilities to be accessed.

On 15th January the locomotive was shunted across the Heritage Centre to the outdoor pit road to allow us to get underneath and remove the temporary Bogie Nut and Washer fitted at Llangollen for our move to Crewe. Whilst we were underneath further inspections were made and preparations for future work planned.

The Unknown Warrior is shunted at Crewe Heritage Centre on 15th January 2019 Photo – Kevin West

One issue highlighted by Andy Forster’s report was the poor white metalling and machining of the Motion Bearings. There are issues with the white metal not adhering to the bronze bearings, poor machining and radii not machined to the correct dimensions. All bearings need to be re-done. Llangollen Railway Engineering as the original suppliers were asked to do the work at their own cost and under our supervision, but have so far not committed to doing the work due to staffing issues. We have received a quotation from Statfold Barn Engineering to undertake the work which is under consideration. The costs involved will be recovered from Llangollen Engineering.

David Hughes, Nigel Day and Gerry Paulson take a break from working on The Unknown Warrior. Photo – Kevin West

Due to the issues found with the white metalling of the Motion Bearings, we have decided to inspect all the other parts similarly treated by Llangollen. These include the two Outside Crossheads presently at Tyseley Locomotive Works, the Inside Big End Bearing at Crewe and the Inside Valve Gear Eccentric. To dismantle the Eccentric required the purchase of a slogging spanner, which will become part of the tool kit required for ongoing maintenance of the locomotive. We are slowly acquiring the larger size spanners as they are offered to us or found. If you have any sitting in your sheds that are 1" BSW (Whitworth) or bigger and in good condition, please let us know.

Coupling and Connecting Rods await attention. And the Eccentric following removal from the locomotive to assess the white metalling. Photos – Kevin West

Keith Riches has started work on kitting the BR 16 ton Box Van out as a mobile workshop. Additional shelving has been installed at one end and a workbench will be erected. To enable this to be done we completed a tidy up and sorting of the locomotive parts we have. Our two containers have been sorted into one for locomotive parts and the other for tender parts. A selection of shelving and benches were erected in the tender container to provide storage and working space.

New storage and work bench now available in one of our containers. Photo – Kevin West

As part of the sorting work, all the tender chassis parts were moved to Leaky Finders works in Exeter in early February. This will enable George and Rory to go through the parts and provide an assessment if they can be refurbished or need to be replaced. An assessment of the original Outside Combination Levers has been made. One appears to be damaged, possibly as a result of accident damage on the original locomotive. The lever is bent so the bushes would have to be bored out of square to line up with the related parts. We have therefore decided to have new parts made.

One of the major issues relates to the Centre Driving Axle Crank Pins. These were made and fitted by South Devon Engineering when the wheelsets were assembled. When we finally came to trial fit the Return Cranks it was discovered there was an issue with the keyway cut into the end of the Crank Pins. There has followed a protracted backward and forward discussion regarding the suitability of these parts and plenty of advice from other engineers regarding the way forward. There is no clear way they can be corrected, so we have decided that the best option is to totally replace them. As the original suppliers we have asked South Devon Engineering to provide a plan to replace the Crank Pins. We received a quotation to remove the old pins and replace with new, but not machine in the keyway slot or the stud holes, as they now say they do not have the facilities to do the job! Added to this we would have to pay transport costs to SDE workshops in Devon.

Centre Driving Wheel marked up to show orientation of the Crank Pin. Photo – Kevin West

Further investigation led us to Multi-Tech Ltd. in Ferrybridge, Yorkshire. They have undertaken similar work for Jubilee class Galatea, and provided a very competitive price, including transport and have been awarded the contract. This obviously involves removing the Centre Wheelset, but before this can be removed all the motion work has to be taken down, plus the Brake Gear, Sanding Gear and Springing and many other smaller fittings. This work has been completed and the locomotive was scheduled to be lifted to release the centre driving wheels on Wednesday 13th February.

With the loco off its driving wheels it allows access to complete the riveting of the platforms to the Frame Brackets. All the holes have been drilled ready for the riveting.

LUBRICATION

Nigel Day is continuing to make good progress on the installation of the lubrication system alongside the rectification work. Most of the pipe runs are now formed and the clips installed.

BOILER

Work continues on the boiler. The Barrel is now fitted permanently to the Firebox Assembly and the internal pipework and trays are being manufactured. HBSS are ready to start installing the firebox stays but we are waiting for the insurance company to give the go ahead regarding the stay size, pattern and material. We were under the impression that this had been agreed some time ago, but a change of staff has meant a complete reassessment. This has involved additional drawing and design input to obtain the sign off, which is expected by the end of February. The Dome is due to move to Harrison Engineering for additional drilling in the next few days.

The Dome and cover awaiting additional machining. Photo – Kevin West

TENDER

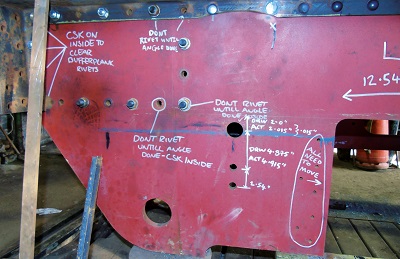

Work on the Tender Chassis continues at Leaky Finders workshop near Exeter. A number of issues regarding work undertaken at Llangollen have been discovered and solutions either found or are in discussion to establish a way forward. A number of holes have been found to be drilled in the wrong positions which will require them to be welded up and redrilled correctly. All very disappointing. The Top Angles have been riveted to the frames, we will then start refitting parts after the stripping down.

Kevin West and George Balsdon discuss the Tender Frames in the Leaky Finders workshop, near Exeter. And the Tender frame marked up for future work. Photos – Kevin West

As stated above, all parts from the original tender chassis are now at Leaky Finders workshop. Most parts are showing the effects of 40 years railway service and another 40 years in scrapyards and open air storage. At least we have the parts to use as patterns and guidance if replacement is decided.The Horn Ties fit across the bottom of the axlebox cutouts in the frames. The ties have to fit correctly to the frames to stop the gap opening or closing as the frame moves. The ties had suffered corrosion and fretting. They have been built up with weld and re-machined to be the correct fit.

A selection of original Tender parts as delivered to Leaky Finders. Photo – Kevin West

THE WAY FORWARD

Alongside the physical assembly work we have been spending a lot of time in discussion with the possible candidates who we have approached about finishing the locomotive. Andy Collinson has been heading up the contact with these organisations, creating the work schedules and fielding the questions. We now have quotes in from three companies and one company has informed us they are unable to fit into our schedule, so have decided not to offer a quote. A fourth option of overseeing the finishing of The Unknown Warrior ourselves is also under investigation.

THE BIG LIFT

Wednesday 13th February 2019 proved to be a turning point in the fortunes of the Project, following our recent setbacks. After months of discussions and planning and a lot of hard manual work in less than ideal conditions, a programme of work was undertaken that will open up real progress over the coming months. The main activity was to remove the Centre Driving Wheelset for replacement of the out of specification Crank Pins. To achieve this, we hired two road cranes to lift the chassis to allow the wheelset to be rolled out. With the chassis lifted the opportunity was taken to complete a range of tasks that would have been either very difficult,or impossible with the locomotive on the ground.

Lifting the chassis at Crewe Heritage Centre on 13th February. Photo – Kevin West

Recently it was discovered that attention was required to five missing rivets on the Drag Box. The leading ones on each side were behind the trailing wheel tyre, so the plan changed from simply lifting the loco to release the Centre Drivers, to releasing both the Centre and Trailing Wheelsets.

A team was assembled to undertake the work, headed up by our resident engineer, Nigel Day and CME Kevin West. Engineering Director, Steve Blackburn acted as liaison with Crewe Heritage Centre and diesel shunter driver. Dave Owen provided technical advice and experience alongside regular volunteers, David Hughes, Gerry Paulson, Brian Greally, Keith Riches and new recruit Tayger Farrow. Our thanks to Ray from Crewe Heritage Centre for his assistance driving the folk lift truck.

Over the last few weeks the Brake Gear had been taken down along with the Sanding Gear in preparation for dropping the wheelsets out. The Lower Centre Slide Bar was removed to allow the Bogie Centre Pin to be removed and sent away for a new nut to be made. On Tuesday 12th February the exhibits in the Heritage Centre, the Class 47 diesel, the Crewe Cab and The Unknown Warrior were shunted to get our chassis in the correct position to be moved out to where the lift would take place the following morning.

Following an early breakfast, I arrived at the Heritage Centre at 8.00am, to find the two cranes already on site. A quick briefing of the crews and they were soon in position and being set up.

Steve fired up the Class 03 shunter and The Unknown Warrior was propelled out into position. The first lift was to remove the cab and place it out of the way. Then came the ‘Big Lift’. With a crane attached to each end of the framework, the chassis was lifted clear of the Trailing and Centre Wheelsets and the Bogie, which were rolled clear. The chassis was then lowered back onto the leading driving wheels and a sleeper stack positioned under the rear Drag Beam. This provided a safe, stable condition for work to start.

The chassis supported on sleeper stacks. Photo – Kevin West

Heritage Boiler Steam Services (HBSS) had arrived to undertake the riveting work on the Drag Box and Platforms. Whist this was underway the team split into two groups, one working on removing the centre driving wheelset axleboxes and springs. The Wheelset was then craned onto the waiting road transport for dispatch to Multi-Tech Ltd., in Yorkshire.

Andy Wilcock from HBSS riveting the platforms. And the centre driving wheels ready for dispatch. Photos – Kevin West

The Centre Wheelset Horn Ties were refitted to keep the Chassis stable. The other team worked under the Cylinders, drilling and tapping the rear Cladding Fixing holes which were not accessible with the bogie in place. Also undertaken was some preparatory work to fit the Inside Cylinder Relief Valves when the loco is lifted again in a few weeks’ time to refit the Centre Driving Wheels. This work was completed in a couple of hours, the chassis was lifted again, the sleeper stack removed and the Trailing Wheelset and Bogie rolled back into position. The rear end was lowered slowly until the Horn Guides engaged in the Axleboxes, then attention shifted to the front end and the Bogie. Once in position and lowered back down the cranes were removed and the chassis shunted back into the Exhibition Hall for HBSS to finish the platform riveting.

The team then cleared away the tools, swept away the debris and retired to the mess for tea and doughnuts. A grand effort, that shows planning and attention to detail brings rewards. From here on we look forward to parts going back onto the locomotive for the final time rather than being removed. A good day. Many thanks to all that made it possible.

Kevin West, CME.