Reduced to £5.00 plus £2.50 p&p

Engineering Up-date - December 2018

A slightly different report for this edition of The Warrior which is centred on our departure from Llangollen and plans for the immediate future.

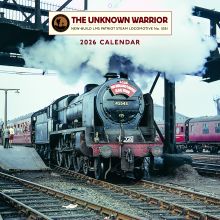

The Unknown Warrior at Crewe. Photo – Kevin West

Despite our best efforts to agree a reasonable schedule of work at Llangollen we were not able to get the tasks completed to our timescales.We had already made Llangollen aware that we were going to put completion of the locomotive, from finished running chassis, which had been agreed would be completed at Llangollen, fitting the boiler and all tasks to a running locomotive, out to tender to a number of possible contractors.

Following the publication of a news item written by a journalist in Steam Railway No. 484 published in mid-September, the Llangollen Railway board informed us that they would not be submitting a quotation to carry out future work on The Unknown Warrior beyond what had already been agreed. We had previously informed Llangollen that we needed the locomotive chassis ready for a trial boiler fit at a location away from Llangollen in October and this was incorporated in the agreed planned work schedule. Following Llangollen’s decision they informed us that after the departure of the locomotive for this planned work we would not be welcome back at Llangollen. We were also asked to remove all of our other property from Llangollen quickly.

The planned movement date for the locomotive chassis was Monday 29th October. There were a number of tasks that Llangollen had agreed to complete in plenty of time prior to the move. It was also agreed that our volunteers would assist in reassembly of parts that had been removed. Progress on this agreed work was not as rapid as we had hoped for in the weeks leading up to the move. On a visit to check progress on 27th September it was found that the new Union Link Pins we had supplied had been drilled by Llangollen incorrectly for the anti-rotation studs. Instead of following the supplied drawing which shows the stud to be pressed into the shaft of the Pin, they had drilled through the head of the Pin. These Pins were rejected and Llangollen had to manufacture six new Pins to the correct design. These new Pins will be fully inspected to ensure they are to specification.

One of the Union Link Pin incorrectly drilled. Photo – Kevin West

As time progressed towards the move we contacted Llangollen Railway on Monday 22nd October to enquire the state of all the tasks and was pleasantly surprised to be told all the work had been completed.

Nigel Day had been continuing to work on preparation of the Lubrication Pipework. As each piece was formed and fitted it was labelled up ready for removal during the movement to prevent damage.

Lubrication Pipework under way on the chassis. Photo – Kevin West

The Lubrication Pipework hanging on the welding bay at Llangollen. Photo – Kevin West

The Lubrication Oil Pots were delivered from John Dunn Engineering and some have been trial-fitted prior to removal for safe storage until required.

An Oil Pot temporarily fitted to the LH Top Slide Bar. Photo – Kevin West

A volunteer working party was arranged for Thursday 25th October, primarily to replace all the platform sections at the front of the locomotive that had been removed to gain access for work around the cylinders. Once on site it was clear the report given on Monday was incorrect and there were still a large number of outstanding tasks.

At this point a more detailed inspection was undertaken and revealed a larger number of issues with work not fully completed or parts that were missing. These were mainly smaller parts which had been removed and now misplaced, meaning they could not be located and refitted. Many items fitted had bolts or nuts missing and all the fastenings, nuts, bolts and washers for the footplating following removal had been lost, so new fastenings had to be ordered to replace them. These did not arrive until the following day, delaying the reassembly work and requiring an overnight stay in Llangollen. In addition the securing cotters had not been fitted to the Valve Guide Slides. Once again these parts had been supplied to Llangollen and subsequently lost.

Valve Guide Slide showing missing cotter and corrosion on the steel work. Photo – Kevin West

The Oil Caps had not been fitted to the Connecting Rods and the Gradient Pins had under-length securing bolts and washers of the wrong design.

The Front Buffers were only held on by two bolts each instead of four. Once this was pointed out extra bolts were found and fitted, but all were of different length. One again this was pointed out and the ends of the over-length bolts removed with an angle grinder which also damaged the nuts. All these will now require replacement. This may seem petty, but it is a sign of quality to have all adjacent fittings the same and undamaged.

The Inside Cylinder Exhaust Pipe had been fitted with bolts that the incorrect length. This had been reported some time previously and agreed that correct length bolts were to be installed.

This had still not been done. We now have been supplied the correct length bolts and will change them ourselves.

The Sand Pipes previously fitted were found to be loose at the bottom ends and required all the bolts tightening. Once the locomotive was moved out of the shed on Monday and placed over the pit it was also found that at the top ends they had only been loosely fitted with just a single bolt. In one case because the bolts fitted were too long, an oversize nut had been used as a spacer to allow the bolt to be tightened.

A Sand Trap showing over length fixing bolts and large nut used as a spacer. Photo – Kevin West

On the Friday the number of outstanding tasks was still large, but suddenly the locomotive was being worked on by an increasing number of Llangollen staff to finish everything off.

One of the main items of concern were the Inside Slide Bars. These had been removed to allow access for further work. They had previously been set up at great time and expense to the correct dimensions with specially made packing pieces to get the bars in the correct position. When these parts were to be replaced the packing pieces could not be found. Replacements had to be made undoing all the earlier good work.

Another issue was the Bogie Centre Pin. At the bottom end is a large 9" diameter washer, held in place by a nut, cotter and split pin. These parts had been made some time ago and fitted along with the bogie at Tyseley. The bogie had subsequently been removed at Llangollen to enable work to be undertaken under the cylinders, including drilling and tapping the mounting holes for the Cylinder Cladding Sheets. This work had been reported as complete and invoiced many months ago. The bogie had been refitted as part of the preparation for the move.

On inspection we found the sheets for the bottom of the Outside Cylinders had not been fitted. We requested these to be installed only to find out they had never been fitted and required trimming and all the holes in the cylinders drilled and tapped. Included in this work are two ¼" tapped holes in the rear end of the Outside Cylinders that cannot be accessed with the bogie in place.An offer to jack the front end of the locomotive up to gain access was refused as it would place a great strain on the locomotive chassis. The locomotive will require lifting with two road cranes to run out the bogie and gain access to these two holes.

On the Bogie Centre Pin itself, the pin was still in position, but on Friday, no washer, nut or cotter was in place. This was reported back to Llangollen who assured us that they would be fitted.

The Front Cylinder Covers had not been fitted as requested and when this was investigated we discovered that following replacement of the Cylinder Cover Studs at the suggestion of Llangollen Engineering eighteen months ago they had discovered the replacement studs to be slightly larger than the originals. The Rear Cylinder Covers had all had the mounting holes slightly opened out to allow correct fitting, but they had not done the Front Covers. Also all the mounting nuts had been lost and replacements had to be ordered.

By the end of Friday there were still a large number of tasks unfinished and the Llangollen staff were asked to work over the weekend to complete everything. We requested a report of progress on Sunday evening and departed for home for the weekend. The following morning, a batch of drawings detailing all the parts believed to be missing and requiring replacement was sent to Llangollen. The snag list finally amounted to 20 items.

Snag List. Photo – Kevin West

A message duly arrived on Sunday evening reporting that all tasks except a few were complete and these would be finished in time for the transporter’s arrival on Monday morning.

We arrived back in Llangollen at 8.30am on Monday morning and did a quick inspection of the locomotive. It was clearly apparent that there was still a significant amount of work to complete. Once again most of the works staff were working on the locomotive.

Work was in progress on refitting the Inside Slide Bars. These were still being set up and measured, from a wire set up through the bore of the Inside Cylinder. This wire was stopping any work on fitting the Front Inside Cylinder Cover and any of the platform and plate work above the cylinder. As the road transporter was due to arrive at Llangollen at 10.30am we instructed all work on setting up the bars to be stopped and all secured for transport to enable the other parts to be fitted.

The road transporter finally arrived at 11.00am, but was unable to enter the yard to set up for loading as the yard had not been cleared for the transporter. This was not undertaken for a couple of hours. The locomotive was finally moved from its position in the shed around midday and positioned over the pit in the works yard. We immediately went into the pit to inspect the locomotive only to find the Bogie Centre Pin had been fitted with the wrong nut and washer and the cotter used was loose. Also several nuts were missing from the Axlebox Horn Ties, plus no cotters were present with these nuts. The large washer found to be missing from the Bogie Centre Pin is there to stop the bogie dropping if the loco is lifted. We were not prepared to allow the locomotive to be loaded up onto the road transporter without such a safety feature in place. Llangollen Engineering then proceeded to make a temporary replacement part from a piece of plate taken from our old Tender Frames. This was without asking if they could use our material.

The blank for the temporary Washer flame cut from a piece of our old Tender Frame Plate!. Photo – Kevin West

The locomotive was shunted out for loading at around 3.30pm, finally leaving Llangollen much later than planned at 5.00pm.

The chassis being loaded onto the road transporter at Llangollen. Photo – Kevin West

Leaving Llangollen yard. Photo – Kevin West

As it would have been dark when the locomotive arrived at Crewe after a two hour road trip it was decided that it would be taken to an overnight storage depot in Stoke-on-Trent. The Chief Engineer followed the loco to Stoke before diverting to Crewe for another unscheduled overnight stay to be ready for unloading the following day. The locomotive was finally delivered to Crewe Heritage Centre at 10.30am the following day. This late departure caused additional overnight storage charges and staff costs for the delivery on the Tuesday which are to be recovered from Llangollen.

5551 is slowly winched down the ramp onto the track at Crewe Heritage Centre, 30th October.. Photo – Kevin West

Safely inside the Heritage Centre. 30th October. Photo – Kevin West

A number of cars and vans were also loaded up with smaller parts ready for movement either to Crewe or safe storage until required.

The locomotive fittings loaded up for removal to safe storage. Photo – Kevin West

The volunteer team returned to Llangollen on 30th October to finish loading the projects’ 12 ton box van and storage container, ready for their collection and delivery to Crewe later in the week. Despite our previous agreement that the Tender Frame would stay in the loco shed at Llangollen until we had undertaken some additional work to stabilise the assembly, it was shunted out of the works on Tuesday 30th October and placed on the departure road.

The Tender Frames after movement out of the works on 30th October. Photo – Kevin West

The reason given by Llangollen was that it was to be collected that week. We have no idea where this information was obtained as we had by that time neither placed an order with the selected contractor or arranged transport. We now have a Tender Frame that will have to be inspected and levelled once again as we are unsure how it was lifted to move it? The Box Van was moved to Crewe on Friday 2nd November and the container early the following week, to join a second container that had been purchased as a possible workshop.The Tender Frame and associated parts left at Llangollen are expected to move to Devon in the week commencing 26th November.

Once the locomotive had arrived at Crewe, work started to prepare the chassis for the trial-fitting of the boiler assembly. Unfortunately, I was unable to attend the trial fitting due to a family bereavement, so Andy Collinson will take up the story for the day. Just before midday on Monday 5th November, the boiler and smokebox of ‘The Unknown Warrior’ pulled into the yard at Crewe Heritage Centre ready for its trial fitting into the frames of 5551.

Andy, Rob and the team at HBSS had an early start at 6.00am in order to manoeuvre the boiler and smokebox out of their works to be loaded onto the trailer of W. J. Baldon and Sons of Exeter for the journey from Huyton to Crewe. The JCB was quickly pressed into use so that the chassis could be towed out of the hall and the cab could be lifted. No sooner than this had been done, the chassis was swiftly moved back inside so that the smokebox followed by the boiler could be lifted and placed on the hard standing. The JCB then carefully lifted up the smokebox where it was offered up to the front tubeplate and bolted to the barrel for the first time. The boiler weighing approximately 30 tonnes was then lifted by the impressive Hiab, capable of lifting in excess of 100 tonnes, to clear the road so the JCB could haul the chassis back out of the main hall. The boiler was then carefully manoeuvred above the chassis and gently lowered into position between the frames. Well almost!

One of the concerns HBSS had already anticipated was that the heads of the temporary fixing bolts holding the outer and inner firebox together around the foundation ring could potentially cause it to be too tight a fit. Of course, it will be riveted flush when it is finished and will not be an issue. After a little attention to the bolt heads with the assistance of Rob holding a grinder, the boiler was again lifted and after some careful final positioning, ‘The Unknown Warrior’ had her boiler in place for the first time creating the most fantastic and emotional sight. By 4.00pm the cab had been lifted back into place, the whole ensemble was tucked back inside the main hall in the fading light for further alignment work and preparations for the Armistice weekend to begin. We must give a special thank you to HBSS and their team for what was truly a very slick and superbly organised operation, a real credit to everyone involved on the day. Back to Kevin.

Following the successful trial fitment work continued to check alignment of the boiler shell by Heritage Boiler Steam Services. Alongside this our volunteer gang were working on preparations for the AGM and Open Weekend.

Work underway to prepare the locomotive for the AGM. Photos – Kevin West

Work undertaken included refitting the Smoke Deflectors and Chimney, plus a deep clean of the locomotive.

The Chimney is lifted in preparation to re fitting. Photos – Kevin West

Gavin Shell starts work on cleaning the Smokebox. Crewe 9th November. Photo – Kevin West

Work was also in progress on the Smokebox Door to enable the LMS number plate to be fitted for the first time. New mounting holes were drilled to the correct distance. Previously, the locomotive has only carried the BR number 45551 on the Smokebox Door.

Nigel Day and David Hughes mounting the LMS Number plate on the Smokebox Door for the first time. Crewe 9th November. Photos – Kevin West

The afternoon of Thursday 8th November, saw the arrival at Crewe of the tender from the East Lancashire Railway ‘Crab’ No. 13065. This was unloaded and placed in the exhibition hall about 30 feet away from No. 5551. The new crests had been delivered from Procast earlier in the week, these had been drilled in readiness for mounting on the nameplate backplates, so one final task was fitting them. Once in place they were covered over in preparation for unveiling the following day.

Gavin Shell covers the newly fitted Crest. Crewe 9th November. Photo – Kevin West

Friday 9th November saw a larger group of volunteers assemble for a final day of effort to get the locomotive ready for the weekend. Mike O’Connor from Heritage Painting arrived to hand paint the locomotive number onto the cab side. Engineering Director, Steve Blackburn was dispatched to find some paint that matched the colour of his car to enable all the Crimson Lake to be applied to the right hand side of the locomotive, whilst the Buffer Beam was repainted and various sections of the black around the front end were touched up. At around 4.00pm the tender from 13065 was pushed up against the locomotive rear beam to give the first view of an almost complete Patriot since 1962.

Chief Engineer Kevin West stands with 5551. Crewe 9th November. Photo – Andy Collinson

The parts for the Reverser Shafts had been delivered from Harco Engineering earlier in the morning and were arranged for display alongside the Lubrication pipework.

The parts of the Reverser Shafts. Photo – Kevin West

Following the locomotives’ arrival at Crewe we had been visited by ex-works staff interested in what we are doing and by people that have been involved with other locomotives in recent years. During their walks round the locomotive we have been made aware of several issues that may require further investigation or re-work. These include poor white metalling of Coupling Rod Bearings. One individual picked up the fact that the Connecting Rod Big End Bearings had different details on the inside edge of the white metal, one has a radius the other had a chamfer, when in fact they should both be square. These will both need to be redone. Other bearings show white metal on the end faces that has not been machined smooth. A full inspection will now be undertaken on all work undertaken on these motion parts.

A Big End Bearing showing poor machining and casting of the white metal Photo – Kevin West

The LH Trailing Crank Pin after removal of the Speedo Drive Crank showing excess white metal on the end of the bearing not removed. Also, the 2 Drive Dowels have not been fitted. Photo – Kevin West

Away from the locomotive work continues on the procurement of parts for the locomotive. Recently received from the foundry are castings for the Piston Rod Squab Boxes, three new Drain Cock Body castings and the Ejector Exhaust Pipe.

A recent batch of castings collected from the foundry. Photo – Kevin West

Following the observation of the two minutes silence on 11th November we were able to have a bit of fun. The Chief Engineer had been persuaded to bring his 7¼" gauge Bassett-Lowke tank locomotive to run on the miniature railway. Once in steam, several members of the team plus partners and my daughter, Emma and her husband were given the chance to drive on the miniature railway track.

Emma Moore, the Chief Engineer’s daughter looking very pleased with her efforts whilst driving on the miniature railway. Photo – Kevin West

Once the weekend was over the locomotive quickly changed appearance again. On Tuesday 13th November the cab was removed and the boiler lifted back out of the frames and taken back to the HBSS base at Huyton for the build to continue. Whilst the boiler looks substantially complete it hides the fact that for the next few months a lot of work is required inside the shell to fit out all the internal pipework, support structures, and that’s without even thinking about the thousands of stays to be made and fitted.

On the locomotive chassis, the first task to be undertaken is a full mechanical inspection of work completed so far. This is being undertaken by Andy Forster, former CME of the West Somerset Railway. Andy is completely independent of any of the contractors who are bidding for the contract to complete the locomotive or Llangollen Railway, so we will get a completely unbiased report. Once this is received we will need to try and come to an agreement with Llangollen Railway over how any issues raised will be solved. At the same time, we are in discussion with South Devon Railway Engineering regarding the issues we have discovered with the Driving Axle Crank Pins. Once again we have had an independent report on these parts and presented it for SDR to comment. At present we are waiting for their formal reply.

Besides the four possible contractors who have expressed an interest in quoting for the completion works we are also looking into the possibility of setting up our own workshop and doing it ourselves. We have Nigel Day on board and expressions of interest from several other well respected engineers. There is much to go over and plenty of questions to answer before we make a final decision.

Interesting times, but one thing is clear. From here on we are in control. We are going to build this locomotive once and we will do it correctly!