Engineering Update - Jan 2016

Locomotive Frame Assembly

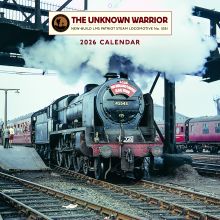

Work continues on the construction of The Unknown Warrior at number of locations.

The big news for this month is The Unknown Warrior became a 4-6-0 on Wednesday 4th February at Tyseley Locomotive Works, with the fitting of the bogie. This was accomplished by using the ex-Ipswich wheel drop. The completed bogie was lowered into the drop before the locomotive was rolled into position above. The bogie was then raised up into position. After a few nervous moments to check clearances and an adjustment to a Stretcher the bogie reached its correct position taking the weight of the front end of the locomotive.

The bogie in the wheeldrop at Tyseley, prior to being raised under the locomotive. Photo – Bob Sweet

The bogie in position under the locomotive. Photo – Kevin West

The Unknown Warrior stands alongside fellow LMS express passenger locomotive 6201 Princess Elizabeth at Tyseley Locomotive Works, 4th February. Photo – Kevin West

The replacement Valve Liner castings are now in the final stages of machining and once complete will be moved to Tyseley Locomotive Works for shrink fitting into the Cylinders. Unfortunately, two of the replacement Cylinder Liner castings have also proved to be unacceptable with similar issues and we are now waiting for further castings.

The six Valve Liners almost finished machined. Photo – CMS Cepcour

Shortly before Christmas some issues were found with Stretcher 4 on the Frame Assembly. As various areas had previously been found problematical and repaired on this casting and it is believed further distortion has occurred it was decided to replace the casting completely. A new casting has been obtained and machined ready to fit to the Frames once they arrive back at Llangollen.

Stretcher at Harco Engineering. Photo – Kevin West

Other parts ready to fit to the locomotive Frames once they arrive back at Llangollen include the Reverser Shaft Trunnions. The Sandboxes and Necks are also ready to fit to the Frames.

Reverser Shaft Trunions and Crank Pin fittings at Harco Engineering. Photo – Kevin West

The Sandbox Necks awaiting delivery to Llangollen. Photo – Kevin West

Brake System and Lubrication System

Refurbishment of the Locomotive & Tender Brake Cylinders from 8F 48518 continues at Harco Engineering.

Brake Cylinders under overhaul at Harco. Photo – Kevin West

Design work continues for the lubrication system. The new body and lid castings for the Mechanical Lubricator are at the Great Central Railway, Loughborough for completion of the large mechanical lubricator.

Design work for the lubrication pipework runs, fittings and clips continues.

The Brake Hangers are being machined by Llangollen Engineering. Drawings for the associated Pins, Nuts etc have been finished and sent out for quotations.

Pistons, Valves and Motion

As detailed at the beginning of this report the original castings obtained for the cylinder and valve liners had to be rejected due to casting faults. The Valve Liner are now in final stages of machining and replacement castings for the Cylinder Liners are awaited from the foundry.

The castings for the Pistons have been delivered to Tyseley ready for machining. Tyseley are going to supply completed Piston and Valve assemblies including matching the Crossheads to the Piston Rods. The new Inside Crosshead will be delivered to Tyseley following machining and the 2 original Outside Crossheads will move from store at Llangollen to Tyseley for this work to be completed. Drawings for the Gland and Stuffing Box parts for the Piston Rods and Valve Rods are in progress to enable manufacture.

Llangollen Railway Engineering are also progressing the manufacture of the Coupling Rod Bushes and Brasses.

Machining of the Expansion Links is almost complete at CMS Cepcor.

The Expansion Links after machining. Photo – Kevin West

Drawings for the pins, nuts and other parts required for the Big End assembly have been finished and delivered to CMS Cepcor to manufacture.

An order for the Eccentric Sheaf Halves has been placed with CMS Cepcor.

The Eccentric for the inside Valve Gear after machining at Harco Engineering. Photo – Kevin West

CAD work on the Inside Eccentric Rod has been completed and will be sent out for quotation soon.

Castings for the Big End Bearings have also been procured. Quotations for machining to finish are being obtained.

The order for the Eccentric Sheaf Halves has been placed with CMS Cepcor and the flame cut blank has been delivered prior to machining.

The flame cut blank for the Eccentric Sheaf Halves at Rowlescourt Engineering on 11th February. Photo – Kevin West

The Cylinder Relief Valve Body castings that were ordered last month have been cast, but have had to be returned as the casting quality was not as expected. Replacements are awaited from the foundry.

We await delivery of the castings for the valve spring holders. The valves will be ordered next.

Bogie

Assembly of the bogie is complete at Tyseley Locomotives Works. The final work on the frame was to rivet over the ends of the End Stays to the Frame. This was undertaken at the end of January. The Axleboxe machining was completed prior to being mounted onto the wheelsets, ready for wheeling.

The Bolster Plates and the Bogie Centre Pin have been mounted onto the locomotive chassis using the specially made fitted bolts.

The completed Bogie Frame being lowered onto its wheelsets at Tyseley. Photo – Kevin West

The completed Bogie Frame at Tyseley Locomotive Works. Photo – Kevin West

Boiler

Preparation work continues at Tyseley Locomotive Works for the forming of the Outer Firebox Steel Flanged plates.

The cast forming block for the Doorplate is at Tyseley waiting for work to start. Detailed discussions have been had with Tyseley on the Forming Blocks for the more complicated Throat plate. We will require 5 different blocks to enable the complicated shape to be hammered into the steel plate. Quotations for the castings have been obtained and once the final details have been sorted they will be ordered.

The Outer Firebox Wrapper sheets been welded at Deepdale Engineering in preparation for delivery to LNWR Heritage,Crewe.

Inner Firebox assembly underway at LNWR Crewe. Photo – Gavin Shell

At LNWR Crewe, the Inner Firebox assembly is starting to take shape, with drilling of the plates taking place prior to a start being made on assembling the parts of the copper firebox together. The copper Crown and side sheets welding is due to be completed in the next couple of weeks.

The 2 barrel rings are ready to be riveted together when there is capacity in the works. The Foundation Ring components are ready to be sent away for machining before welding in the side sections.

Discussions are underway with our Boiler Insurance company regarding the design and manufacturing processes for the Dome and Cover. The original was made from 3 pieces and each part would have been pressed from sheet steel of the required grade. The tooling for this would be very expensive to produce just 1 part. Discussions at present are looking at either casting or fabrication as suitable methods.

CAD Data image of the Dome. Photo – Kevin West

LNWR Heritage have agreed the completed boiler will be ready for delivery in January 2017.

Tender

Work on the refurbishment on the Tender Frames continues at Rowlescourt Engineering.

Due to an increase in the commercial workload at Rowlescourt, completion of the Chassis restoration was delayed beyond the expected completion at the end of December. Work has now re-started with good progress made.

The new dragboxes for both front and back have been machined and tack welded into the completed frame assembly. A few finishing jobs a required before the chassis is moved back to Llangollen around the end of February.

Mathew Walker guides the new Front Drag Box into place in the restored Tender Frames at Rowlescourt Engineering on 11th February. Photo – Kevin West

Mathew Walker and Andrew Kennedy from Oakwood Visuals inspect the new Front Drag Box in place at Rowlescourt Engineering on 11th February.. Photo – Kevin West

Mathew Walker clamps the new Front Buffer Beam into place. Photo – Kevin West

Once back at Llangollen work will start to replace all the rivets removed during the Frame Restoration. This will be undertaken by both the Llangollen Engineering staff and our members Jordan Leeds and Matt Jervis on a volunteer basis. Both Jordan and Matt are members of the Llangollen Engineering boiler shop staff.

Design work on the new tank which will be of welded construction with dummy rivets is continuing taking into consideration the requirements for new main line running regulations.

With the Tender chassis back at Llangollen a start can be made on refurbishing the axleboxes and preparing for the chassis to be wheeled. Some work is still required on the Brake gear before it can be refitted.

Future work planning

Following fitting of the Cylinder & Valve Liners and the Bogie assembly at Tyseley Locomotive Works, the locomotive will return to Llangollen. This is now expected to take place in February.

Once back at Llangollen work will continue on setting up the Inner Slidebars.

A start will also be made on the lubrication pipework.