Engineering Update - December 2014/January 2015

Locomotive Frame Assembly

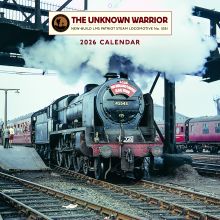

The Unknown Warrior’s frost covered nameplate catches the sun outside Llangollen shed. 3rd December 2014

Photo – Kevin West

Before we get into the detail of this progress update I must apologies for the delay since the last report. In no way is this due to lack of items to report, in fact there is much progress over the last 10 weeks. Time has therefore been devoted to supporting the ongoing work instead of compiling the report.

Work on the painting of the locomotive frames and Driving Wheels continued through November by our volunteer painting gang. In addition they have also painted the frames of an industrial locomotive under overhaul at Llangollen works.

Painting continues on the Driving Wheels.

Photo – Kevin West

On 3rd December the locomotive was lifted off its Driving Wheels in preparation for the next stage of assembly work on the chassis. The Smokebox had been removed prior to the lift. The Frame Assembly was set up on stands and leveled. Work then commenced on preparation for fitting the cylinders.

45551 being lifted off its wheels outside Llangollen shed. 3rd December 2014

Photo – Kevin West

The Driving Wheels were placed onto a well wagon and work has continued on filling, rubbing down and painting by our volunteer gang.

Filling, rubbing down & painting continues on the Driving Wheels.

Photos – Kevin West

The Inside Cylinder has been temporarily flitted and lined up to the Driving Axle centre. As the Inside Cylinder has to be removed to machine the Outside Cylinder fixing holes, dowels have been fitted to enable correct alignment to be obtained once it is replaced.

The Outside Cylinders were delivered to Llangollen just before Christmas, but one returned to Harco Engineering for a small amount of additional work, straight away. This has now returned to Llangollen.

The left Outside Cylinder has been mounted on the frames and lined up, temporarily bolted in position and doweled for alignment.

Left hand Outside Cylinder in position on frames.

Photo – Kevin West

Both outside Motion Brackets have also been temporarily mounted and aligned. The right side Cylinder is due to be mounted and aligned next week.

Left hand Motion Bracket being positioned on the frames by Arwell and Chris from Llangollen Engineering. Andrew Kennedy films progress in the background.

Photo – Kevin West

Lining up these parts is done using a laser projected line to show the horizontal centre line through the driving axle centre. The centre line of the Cylinders is shown by a length of thin wire set up to pass through the cylinder bore and axle centre. This can be seen in the follow couple of pictures.

The Cylinder centre wire set up to check Cylinder and Motion Bracket alignment. The red laser projected horizontal axle centre can also be seen.

Arwell checks the slide bar gap in the Motion Bracket is correctly spaced from the motion centre line.

Photos – Kevin West

The three Hind Cylinder Covers have been machined and delivered to Llangollen. The six Slidebars should arrive in the next few days, which will allow the whole Cylinder, Slidebar, Motion Bracket assembly to be set up and checked. All the cylinder mounting holes will then be reamed to final size and the fitted bolts machined to permanently fit the Cylinders to the Frame Assembly.

Towards the rear of the Frame Assembly, the Boiler Expansion Brackets have been riveted in place and painted.

The boiler expansion bracket is position on the Frame Assy

Photo – Kevin West

Orders have been placed for the patterns and castings for the Front Cylinder Covers and both Front and Hind Valve Covers. Patterns and castings for the Pistons will follow shortly.

Existing design work is concentrating on the remaining Valve Gear parts required. A recent visit to the National Railway Museum Search Engine resulted in finding a further 36 Jubilee class drawings that were not listed in the museum’s lists. Some of these will be useful to the Patriot build where we have no original drawings.

Patriot Project Chief Engineer discusses progress with Arwell & Chris from Llangollen Engineering.

Photo – Oakwood Visuals

Pistons, Valves and Motion

Machining of the Motion Girders is underway at Harco Engineering. These will be fitted on arrival at Llangollen. Final fitting of the Cylinders etc is expected to take 3-4 weeks.

The Hind Cylinder Cover after machining.

Photo Kevin West

The valve heads have been cast as part of a bulk order that include identical parts for Jubilee class locomotives Bahamas, Koluhpur and Leander. They are at Tyseley Locomotive Works for machining. Tyseley will also be supplying the Pistons and Piston Rods, drawings for these have been completed and a pattern for the Piston casting is about to be ordered.

Manufacture of the Coupling Rod Bushes and Brasses is expected to start soon.

Bogie

Detailed discussions continue with Tyseley Locomotives Works regarding assembly of the Bogie.

The Frame Plates have returned to Tyseley after drilling and machining.

The Frame End Stays and Spring Stays, machined by Harco Engineering are now at Tyseley.

The two new wheel centre castings for the second axle await machining. That short statement does not cover the amount of work undertaken on the new axle assembly without any actual action taking place! Since the Driving Wheels were assembled 18 months ago a new regulatory standard has been introduced.

South Devon Engineering, who assembled our Driving Wheels are not at present certified to the new requirement for assembling wheelsets, although the certification is expected to be in place by the time we require our set assembled. For our wheelset we do not have the original drawings for the parts used on the ex 8F set we already own. We do have the wheel centre drawing for the replacement wheels fitted to Jubilee and Re-built Patriot class locomotives. This drawing was used to create the new parts we have had cast. For the axle we do not have the correct drawing, but during the NRM search we found 2 drawings of similar axles. These will be used as technical backup for a new drawing to prove the correct engineering interfaces.

As part of the new requirements we were initially informed that machining of Axle and Wheel Centre would have to be done by an approved supplier, which would have added considerably to both the timescales and costs. Thankfully, we have now been informed that only final machining of the areas where the Wheel Centre is pressed onto the Axle needs to be done by an approved supplier, so we can get the rest done by one of our contractors. We expect that South Devon Engineering will do this final machining prior to pressing the Wheels onto the Axle.

Boiler

Work continues on the forming blocks for the outer firebox Steel Flanged plates at Tyseley Locomotive Works.

At LNWR Crewe, forming the Inner Firebox flanged Throatplate is finished. Drilling of the tube holes is required to finish. Work on joining the Firebox Sidesheets and Crown to complete the Firebox Wrapper is about to start. The Wrapper, Doorplate and Throatplate can then be assembled to complete the Inner Firebox. This is on schedule for the end of February 2015.

The Inner Firebox Throatplate after forming at LNWR Heritage January 2015

Photo – Gavin Shell

Detail work on the new drawings required for the boiler continues.

Tender

Work on the refurbishment on the Tender Frames continues at Rowlescourt Engineering.

The design for the new tender tank has been progressing when time allows.