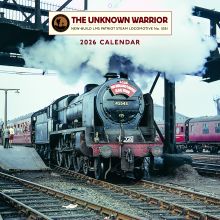

Engineering update - January 2013

| Following on from the assembly of the three 6' 9" driving wheelsets for 'The Unknown Warrior' at South Devon Railway Engineering last year, quartering and fitting of the crank pins has now taken place. There are four different designs of crank pin that are needed for 'The Unknown Warrior'. The quartering of the crankpins ensures the correct alignment of the crank pins in relation to the cranks and axles. The lining up for this job took nearly two hours per crank pin, while the boring process took around a day to complete for each hole, with each cut taking around 15 minutes. About 30 cuts were required, depending on the final size of hole needed for each crank pin. South Devon Railway Engineering is believed to be the only railway engineering workshop that can do traditional crank pin quartering. Six new driving wheel axle boxes were delivered from FHT, at Southam where initial machining was undertaken. During January, the axle boxes were taken to Tyseley Loco Works where final machining will take place. The pattern for frame stretcher number 5 was completed by patternmaker Eddie Mocroft, at the Boro Foundry at Lye, in the West Midlands. This will enable the fifth and last frame stretcher to be cast for 'The Unknown Warrior'. This should be completed in around four weeks, and will be taken to the Llangollen Railway Works and fitted to the frames of 'The Unknown Warrior'. Once this is fitted, the frames will then be correctly aligned before being riveted together. The frames and new metalwork will then be prepared for painting before the driving wheels are fitted to create the rolling chassis. Design work of the front bogie has been completed with new drawings made to enable Stanier 8F wheelsets, horn guides and axle boxes to be used for the front bogie. One wheelset and other parts have already been obtained from Stanier 8F 48518. The other wheelset and parts are expected to come from a Turkish 8F thanks to the Churchill 8F Group. Brass castings for lubrication parts were delivered during January. These require final machining. Alloy casings for the mechanical lubricators have been ordered. The inner parts of the lubricators have already been obtained from South Africa, and will be refurbished for reuse in the new cast casings. |

|